Magnesium Pipe Grades

Magnesium pipes are typically produced using wrought magnesium alloys, known for their excellent strength-to-weight ratio and machinability. Common grades include:

- AZ31B: Mg-3%Al-1%Zn. Offers good strength, excellent formability, and weldability.

- AZ61A: Mg-6%Al-1%Zn. Higher strength and better corrosion resistance than AZ31B.

- AZ80A: Mg-8%Al-0.5%Zn. High strength and good corrosion resistance.

- ZK60A: Mg-6%Zn-0.5%Zr. High strength and good fatigue resistance.

- WE43: Mg-Y-RE (Yttrium, Rare Earth). Exceptional strength-to-weight ratio and high-temperature performance.

These grades are manufactured in various tempers, such as F (as fabricated), O (annealed), and T5 (artificially aged), adhering to standards like ASTM B107/B107M-13.

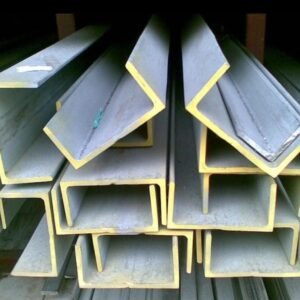

Dimensions & Specifications

Magnesium pipes are available in various sizes to meet diverse application requirements:

- Outer Diameter (OD): 8 mm to 600 mm

- Wall Thickness: Up to 125 mm

- Length: Customizable, commonly up to 6000 mm

Manufacturers can produce pipes in different shapes, including round, square, rectangular, and custom profiles.

Mechanical Properties

Mechanical properties vary based on the alloy and temper. Here’s an overview:

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| AZ31B | O | 230–290 | 170–210 | 10–24 |

| AZ61A | F | 270–390 | 190–240 | 9–15 |

| AZ80A | T5 | 330–360 | 230–250 | 8–10 |

| ZK60A | T5 | 300–340 | 200–230 | 10–12 |

| WE43 | T5 | 290–320 | 200–220 | 8–10 |

Note: Values are approximate and can vary based on specific processing and manufacturing conditions

Applications

Magnesium pipes are utilized across various industries due to their lightweight and mechanical properties:

- Aerospace: Structural components, airframes, and helicopter parts.

- Automotive: Body panels, transmission cases, and engine blocks.

- Medical: Biodegradable implants, surgical tools.

- Industrial Machinery: Gear housings, machine parts.

Reviews

There are no reviews yet.