Magnesium

Our Product Range

Specialty Metals

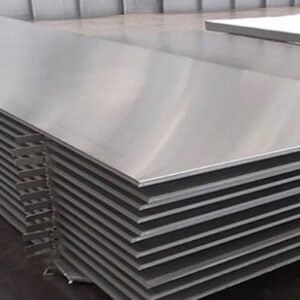

Magnesium (Mg) is a lightweight, silvery-white metal that is the lightest structural metal used in industry.

It is highly machinable, has good strength-to-weight ratio, and is often alloyed with aluminum, zinc, or rare earth metals.

Magnesium

Magnesium (Mg) is a lightweight, silvery-white metal that is the lightest structural metal used in industry. It is highly machinable, has good strength-to-weight ratio, and is often alloyed with aluminum, zinc, or rare earth metals.

- Atomic Number : 12

- Density : ~1.74 g/cm³ (≈35% lighter than aluminum)

- Melting Point : 650°C

- Appearance : Silvery-White

Magnesium Properties

Property | Value |

Density | 1.74 g/cm³ |

Melting Point | 650°C |

Boiling Point | 1,090°C |

Modulus of Elasticity | ~45 GPa |

Thermal Conductivity | ~160 W/m·K |

Electrical Conductivity | ~39% of copper |

Corrosion Resistance | Moderate (improves with alloys/coatings) |

Magnetism | Non-magnetic |

Magnesium Properties

| Alloy | Composition | Features | Applications |

| AZ31B | Mg-Al-Zn | Most common sheet alloy, weldable | Aerospace, automotive panels |

| AZ91D | Mg-9%Al-1%Zn | High strength, good castability | Die-cast parts, housings |

| AM60 | Mg-Al-Mn | Ductile, good impact resistance | Steering wheels, seat frames |

| ZK60 | Mg-Zn-Zr | High strength, heat-treatable | Aerospace, racing components |

| Elektron 21 | Mg-RE-Zr | Excellent high-temp performance | Aerospace, motorsport, defense |

| QE22 | Mg-Ag-RE-Zr | High strength, corrosion-resistant | Helicopter gearboxes, aircraft |

Magnesium Product Forms is available

Form | Description | Applications |

Sheet/Plate | Flat magnesium, AZ31B common | Aerospace skins, laptop casings |

Bar/Rod | Solid form for machining | Machined parts, industrial components |

Ingot | Cast raw form for foundries | Die casting, remelting |

Tube | Hollow cylinders | Lightweight structural parts |

Casting | Custom shapes in dies or molds | Auto housings, gearboxes |

Powder | Fine metal powder | Pyrotechnics, additive manufacturing |

Common Standards

Standard | Description |

ASTM B80 | Magnesium-alloy ingots for remelting |

ASTM B107 | Magnesium-alloy extruded bars, rods, tubes |

ASTM B90 | Magnesium-alloy sand castings |

AMS 4376 | AZ31B-H24 sheet and plate |

MIL-M-3171 | Surface treatments and finishing |

Applications of Magnesium

Industry | Use Cases |

Aerospace | Gearboxes, brackets, frames, structural castings |

Automotive | Transmission cases, steering wheels, seat frames |

Consumer Electronics | Laptop covers, camera bodies, smartphone frames |

Medical | Biodegradable implants (Mg-Ca alloys) |

Military | Lightweight armor, aerospace components |

Sports | Bicycle parts, camera stabilizers, performance gear |

Magnesium vs Other Metals

| Property | Magnesium | Aluminum | Steel |

| Density (g/cm³) | 1.74 | 2.7 | 7.85 |

| Strength (MPa) | ~200–320 | ~200–550 | ~250–900 |

| Machinability | Excellent | Good | Moderate |

| Corrosion Resistance | Moderate | Good | Good |

| Cost | Medium | Low | Low |

Advantage of Magnesium

-

Lightest structural metal (~33% lighter than aluminum)

-

Good machinability

-

High strength-to-weight ratio

-

Dampens vibrations (ideal for automotive/aerospace)

-

Easily recyclable

Dis-Advantage of Magnesium

-

Flammable as powder or thin sections

-

Corrodes easily in salt or moist environments (needs coating or alloying)

-

Low fatigue strength (less suitable for dynamic loads)

-

Expensive than aluminum for some grades